Free Transport Design Course

Automotive Design & Marketing Management

In the last post we saw the crash tests. The development of the vehicle is still ongoing and it is necessary to do a multitude of tests to achieve a competitive and reliable car on the market. Now we will see the engine testing, electronics and safety. Usually the engineering and development teams work separately, on the one hand the team for the powertrain works and on the other hand the team for the development of the rest of the vehicle.

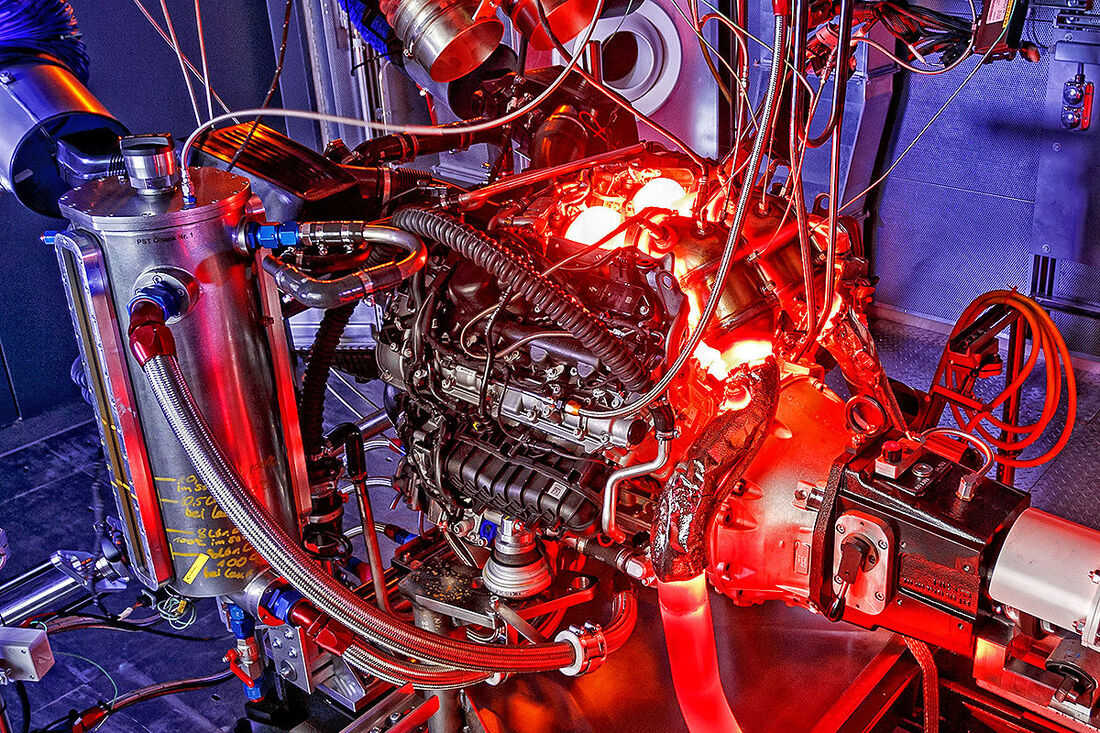

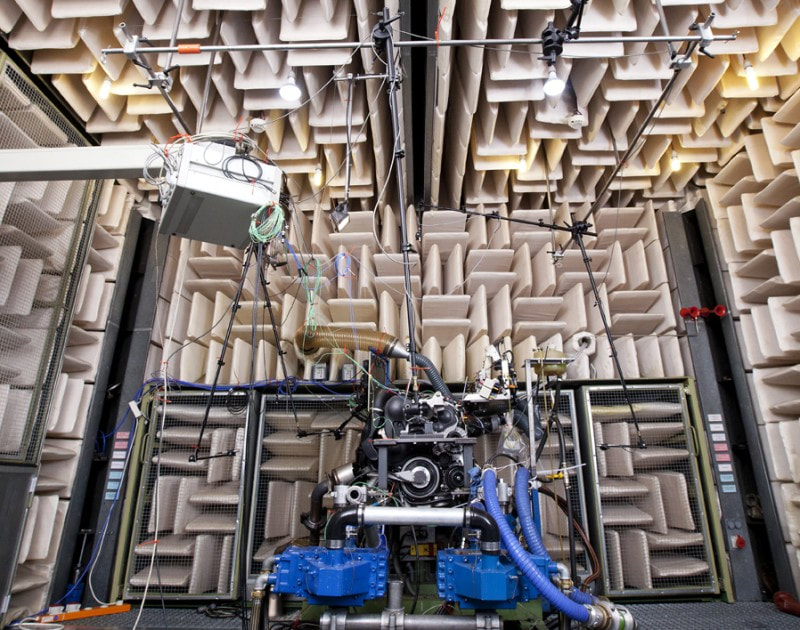

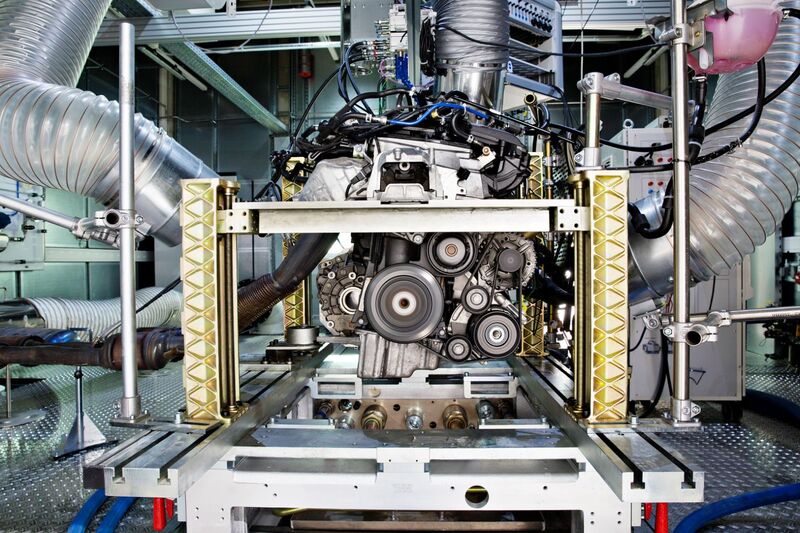

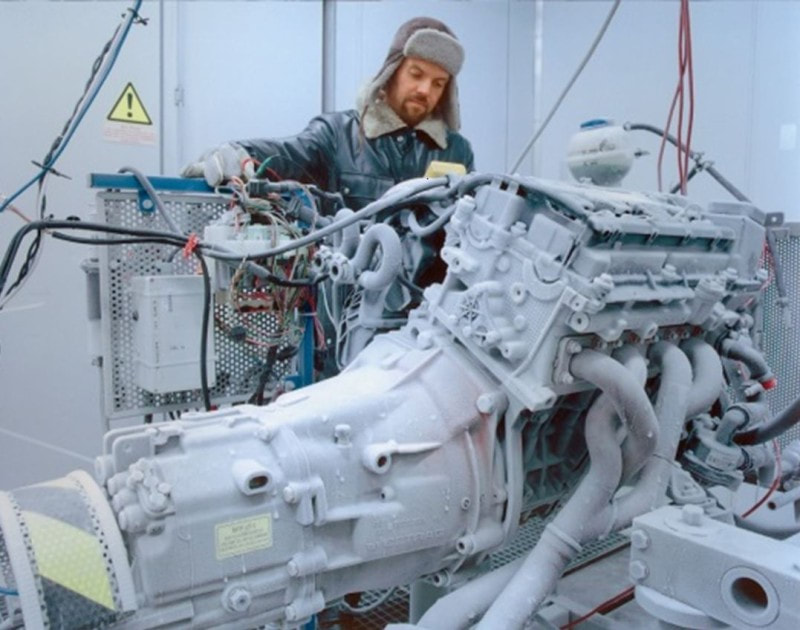

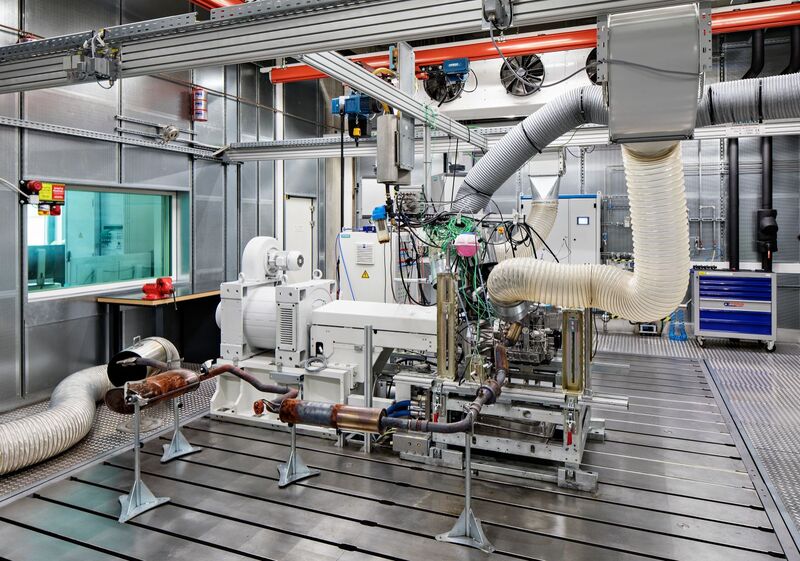

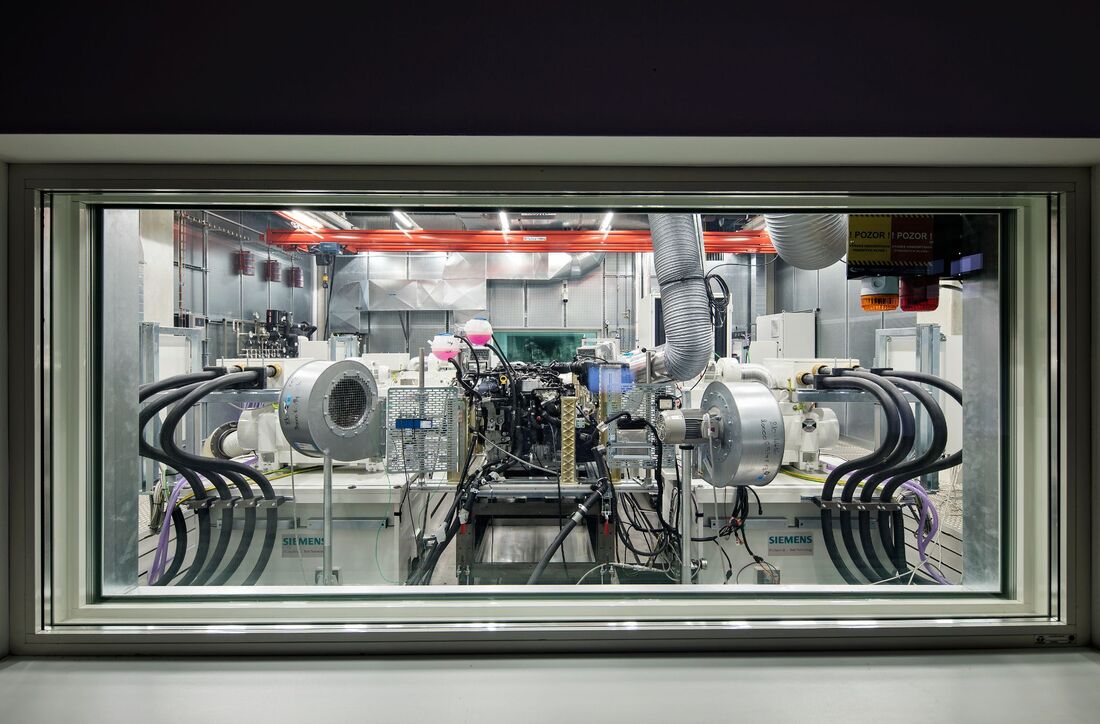

ENGINE TESTING

Engine testingIn this area a multitude of tests are carried out with very different purposes. Car brands can design engines from scratch, but this is something really expensive, so they work on existing engines to improve them over the years. New materials and new technical solutions are constantly being researched. There is also another important task in this area, that of adapting the engines to the different vehicles of the group. For this, the control unit, the cooling system, the exhaust and intake system of each model are optimized. Finally, emissions regulation is becoming increasingly important, so manufacturers are making real efforts to develop cleaner engines. In addition, all these engines are configured for each model to increase the duration of the same. Each engine is tested separately, in a completely isolated room. The bench on which the engine is tested sits on cast iron plates that can weigh 40 tons, and with a complex system of pneumatic suspensions. All this is done to ensure that no type of engine vibration is transmitted to the surrounding rooms, where other engines are being tested at the same time. The isolation system in these rooms is extreme so that no external conditioning interferes with the results. The rooms where the engines are tested are fine, but what is spectacular is not that, but the fact of being surrounded by all the latest technology that hasn't yet come about to the public, and see the engines working flat out, much more than they will ever do on the street. In these rooms is where the magic happens, where the hearts of the cars that are on the street are developed. A single change will impact the performance of all cars, or even a new series of car models. The fascinating part of this is not in the data, nor in the number of possible tests that can be done on an engine, but in the development of the engine itself.

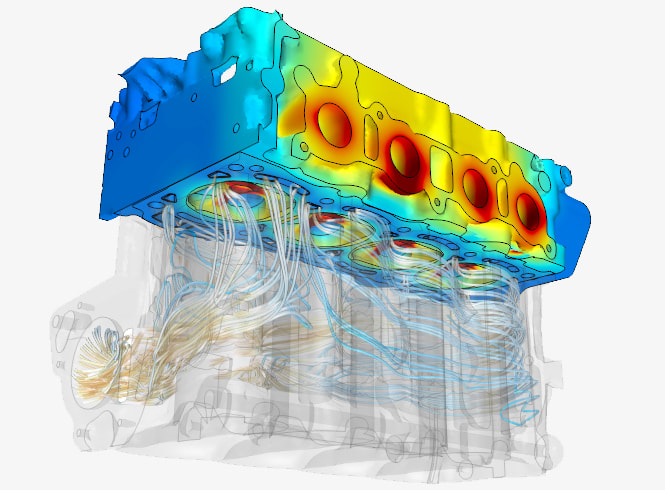

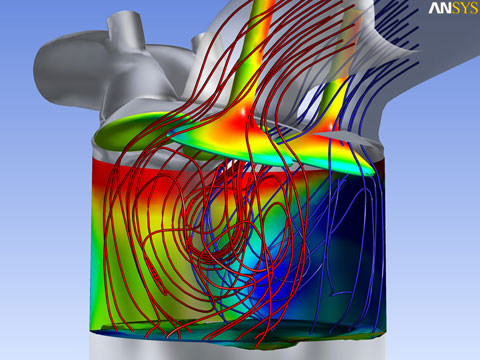

Here also comes into play CFD softwares (Computational fluid dynamics ) to simulate the heat flow prior to the tests, and thus be able to resize the different components, such as the exhaust and manifold. Some of the common programs are Ansys Fluent, OpenFoam, and Simscale. Although there are other options, for example SolidWorks has its own Cfd module, called Flow Simulation. Thanks to these programs we can perform certain simulations, for example:

The great advantage of this is that we can carry out these simulations from our home with any Cfd program, so we can practice on our own. Simulating by computer is inexpensive, that is why manufacturers try to do all possible computer tests, but sooner or later, the engine assembly will have to go to the laboratory to be tested on the engine bench. In this way, parameters such as the engine performance limits, that is, its maximum load, are determined. Emissions, intake air flow, fuel and lubricant consumption, cooling systems, free acceleration, pressure, exhaust gases, behavior against different temperatures, air-fuel ratio for intake mix, among many other variables. In fact, there are specific engine tests for any variable we can imagine, and the test can be as extensive as the manufacturer wishes. It's even possible to introduce the engine under variable humidity, pressure and temperature conditions. The testing possibilities are almost endless, the more budget, time and the manufacturer's interest in developing an exceptional engine, the more tests can be carried out. The engine bench or engine dynamometer also measures braking or rotating resistance, engine vibration, torque for different combinations of gearboxes and transmissions, as well as power input levels. In other words, the behavior of the motor can be fully parameterized, adapting the laboratory machinery for each specific need.

There are many manufacturers and suppliers for any type of engine testing that we can imagine, and if it doesn't exist, it's adapted or manufactured. The problem comes with the real development capabilities, that is, the budget and time available. That is why engine design is so expensive that many brands share engines to save development and testing costs. Even when this happens, these engines are subjected to specific tests to adjust and calibrate it. It should be taken into account that this calibration doesn't impact on a single unit, but will affect thousands of vehicles that will leave the production line. In any case, it should be noted that an engine is a really complex system with thousands of components. When a manufacturer shares an engine with another, although they appear identical on the production line, they often have small differences in materials and finishes. This happens even when the engine starts from the same line since, due to the traceability of the parts, it's perfectly known which engine will go in each vehicle.

Cooling Systems: There is an engineering department in charge of Cooling Systems testing only. Here the cooling systems of the vehicle are put to the limit to check their real limitations. In addition to testing the durability of the system, pulsating pressure, corrosion and erosion of the components, climatic temperature cycles ... etc.

As with engine tests, the difficulty lies in choosing which variables to study and which resources to apply to each one. Under ideal conditions, each of the variables would be studied in all possible scenarios for each of the components, and then for the possible sets of parts. Since this is extremely expensive, it's necessary to find a balance between design and development costs and the final quality of the vehicle. If too many tests are done this will affect the final cost of the vehicle. But the customer doesn't perceive this cost since he is not aware of the number of tests that have been carried out. Therefore we will have a more expensive car on the market without the customer knowing the real reason. But the problem is even greater if it hasn't been tested enough and any problem arises once the car is on the market. As is happening in any company, the best result is always required at the least cost. The engineer will want to carry out as many tests as possible, but cost control and management will try to cut costs as much as possible. Again, we see the importance of being able to perform computer simulations, bringing a breath of fresh air to design engineers, because they can get as close as possible to the final solution and test without generating excessive costs.

ELECTRONICS TESTS

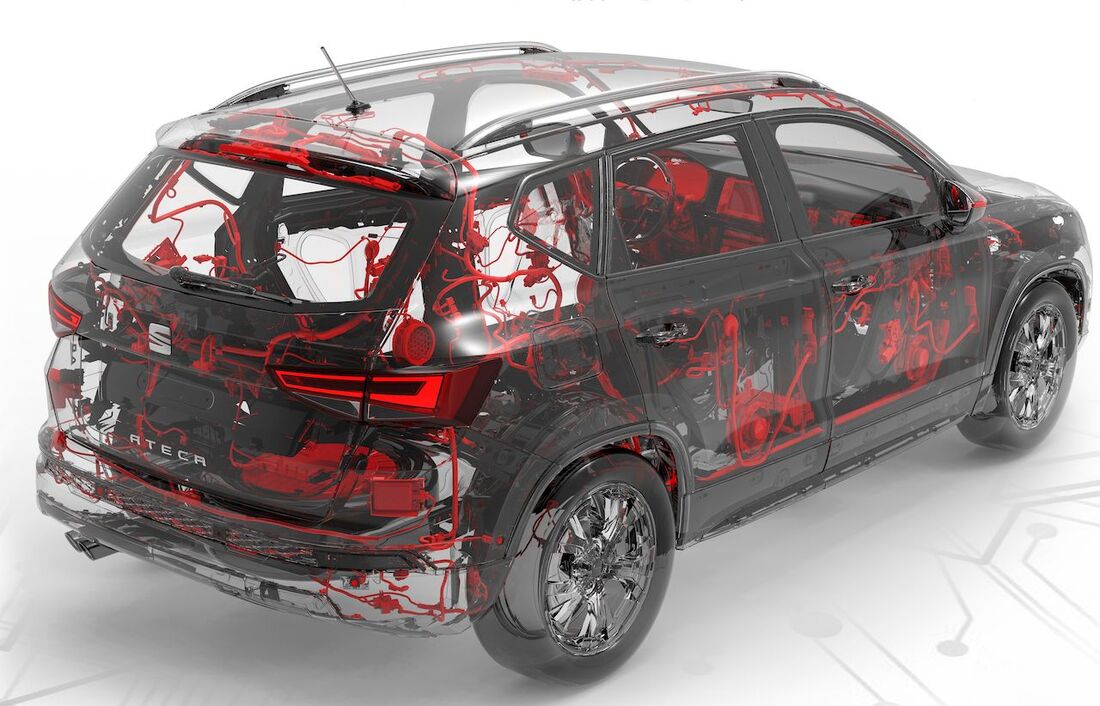

Electronics testsA multitude of EMC tests, HMI and wiring harness tests are carried out. The wiring harness is the entire mass of wiring that a car carries. An internal combustion vehicle carries between 40 and 60 kilos of wiring, which implies between 2 and 4 kilometers of cable. In the 1940s a car had barely 45 meters of cable, this gives us an idea of the importance that electronics is acquiring today. With connectivity and infotainment taking center stage, wiring will increase more and more. In an internal combustion vehicle, the wiring represents 5% of the vehicle's weight, but this figure increases in hybrids (10%), and in electric vehicles it reaches 20% of the car. EMC tests are electromagnetic compatibility tests, which ensure the correct coexistence between electrical and electronic products, avoiding interferences between them. The HMI (Human Machine Interface) tests are carried out to test everything with which the customer interacts, such as the control panels, the speedometer or the light control. There are many tests in this area: vehicle air conditioning, radio frequency and magnetic field emissions, voltage fluctuations, harmonic emissions, electrostatic discharge (ESD), immunity tests to different effects such as magnetic fields, tests of dielectric resistance, insulation resistance and a long etcetera.

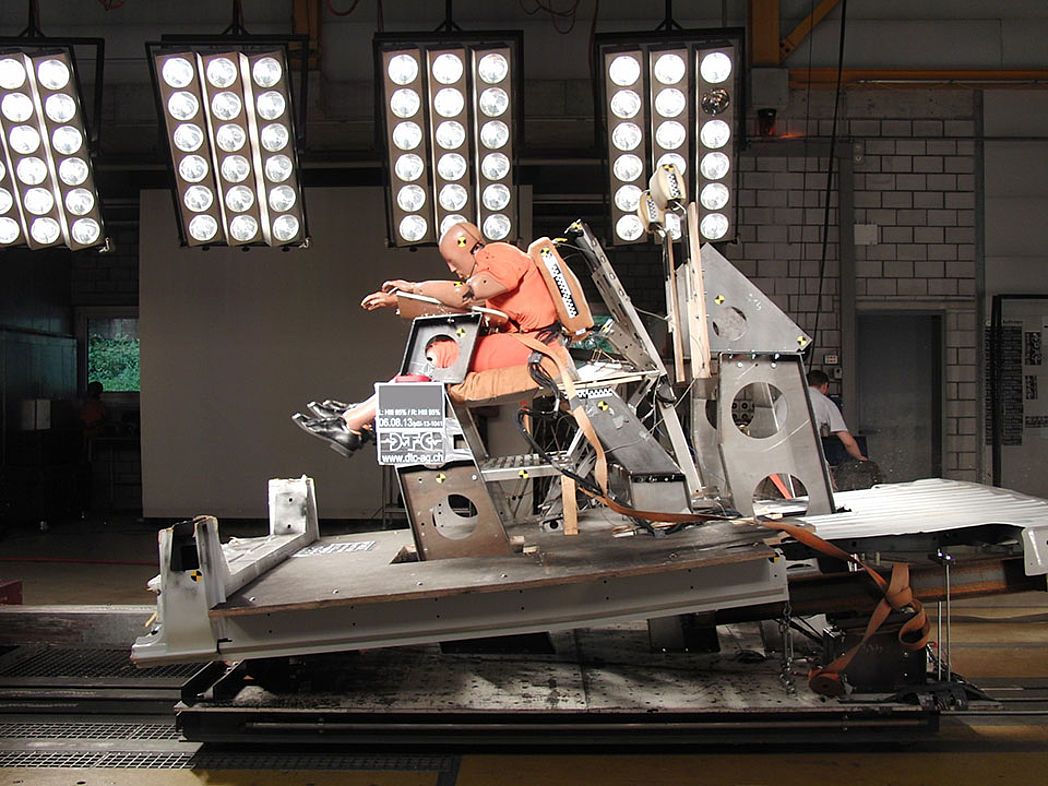

SAFETY TESTS

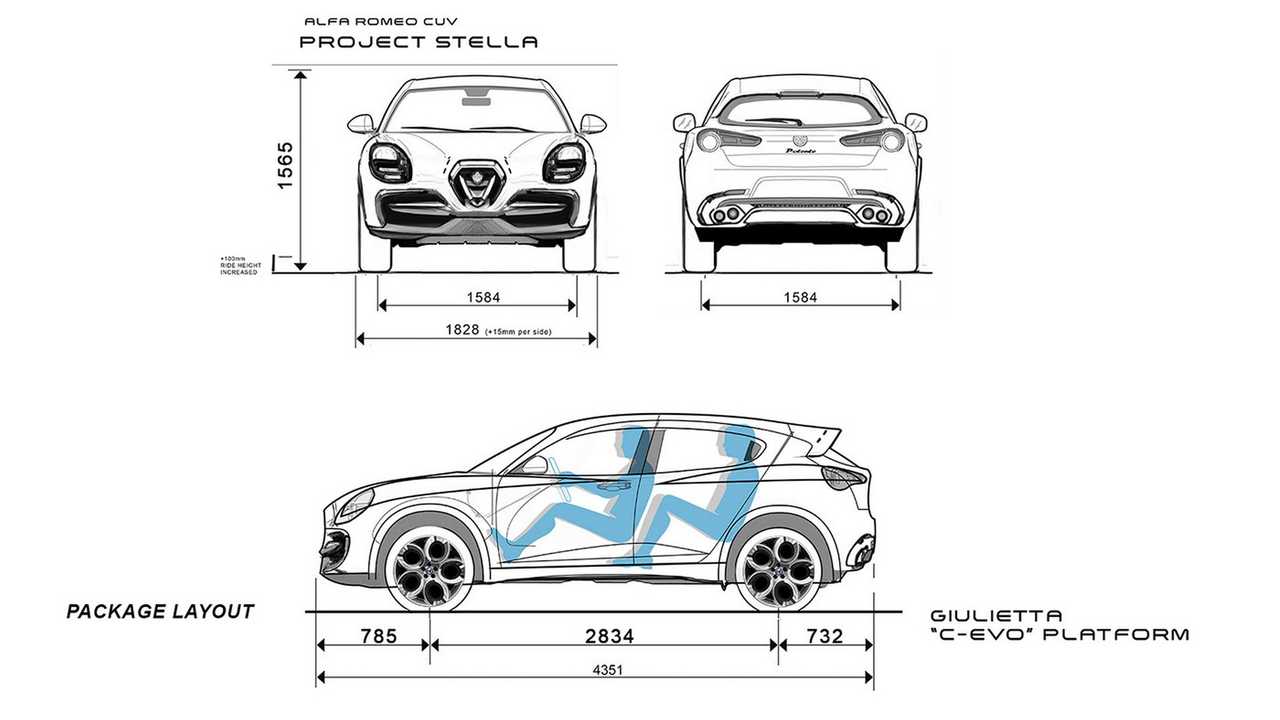

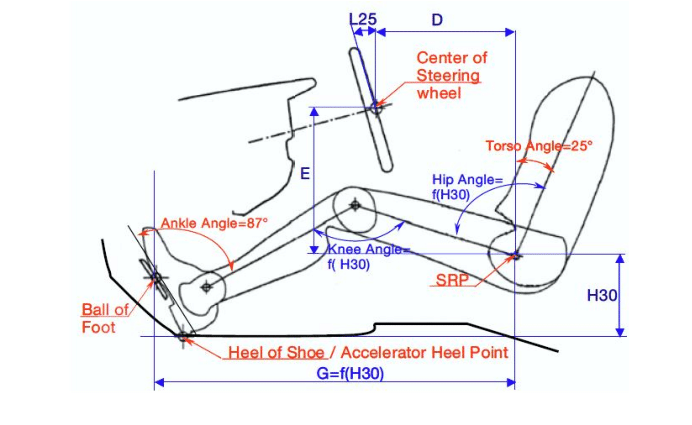

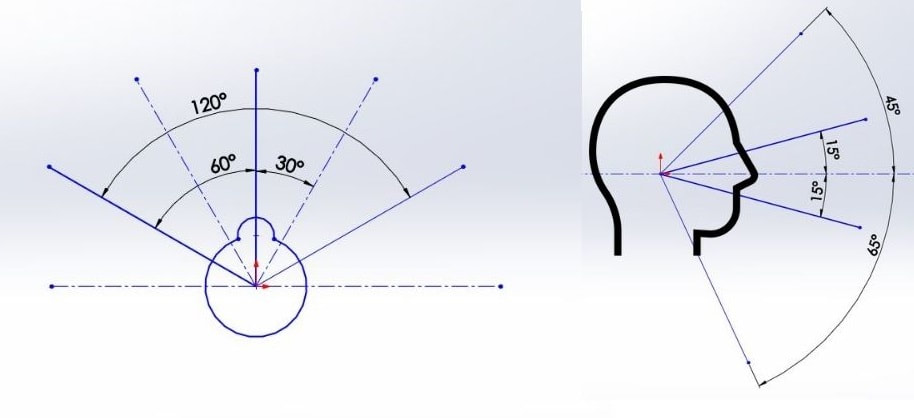

Safety testsIn addition to the crash tests we saw in the previous post, there are other body safety tests inside the vehicle. The ergonomics, usability and comfort of the cabin are studied. In car design, seats are an important component of the so-called feel-good factor. This factor was set by the manufacturers to determine a series of subjective but fundamental factors when selling a car. Keep in mind that the first interaction that a potential buyer has with the car is to get into the driver's seat and put their hands on the steering wheel. If the potential customer feels uncomfortable, they will not buy the car and work five years of development will have been useless. Ergonomics specialists look at any detail in the cabin to reduce the risk of any type of injury. For example, resistance tests are carried out on the seats simulating up to 20,000 continuous uses. This test is carried out using humanoid robots with weights distributed to resemble that of a person. Pistons are also used that have bags covered with denim at their end to apply tension to specific points of the seat in a cyclical way. Seats are also tested under adverse weather conditions, introducing them in climatic chambers and carrying out different fatigue tests. There are also tested the resistance of the IsoFix or Latch restraint systems, which is the system to which child seats are anchored. This is essential since in the event of an impact, this system must be totally secure and not detach from the vehicle. As a design trend, more importance is being placed on comfort and use of time inside the cabin due to advances in autonomous driving. That is why manufacturers study the possible functions that are carried out inside the vehicle. For example, Toyota found that many drivers used the car cup holder to house their mobile phone, which is why they redesign the interior of many vehicles to offer both functions. In turn, it's important that these functions don't distract the driver. Once the vehicles are fully autonomous, this priority will change completely and the driver will be able to make the most of the time spent inside the vehicle without paying attention to the road. Meanwhile, the driver will have to keep his eyes on the road even if the rest of the occupants are using the vehicle's infotainment. As a car design trend, we can see a rise in the importance of ergonomics, not only for safety but also for usability. This will also influence the infotainment of the vehicle, but not always. For example, several studies found the following: when a driver could store his objects, such as glasses or mobile, within the driver's field of vision, the purchase intention of the car increased considerably. Being an emotional factor, it will evolve in a totally different way than ergonomics, since it will depend on the tastes and criteria of the clients. Ergonomics in vehicle design is present from the beginning because the whole design is interdepartmental. Even if a department is in charge of a specific phase, to advance to the next phase, all departments have to give the go-ahead. In the first sketches of the car, the concept designers establish the "package" of the car. This is not the box or the packaging, in automotive design the package means the arrangement of the different elements, such as the engine assembly and the seats. From that initial moment, aspects such as the distances between seats, space with the roof, driving position, legroom, range and limitations of the driver, the driver's vision, are analyzed. Once the designers present the clay model of the car interior, the designers and ergonomists work on the layout of the control controls and everything that is within reach of the driver. This can be done on a computer and even in sketches, there are also really complex studies developed by professionals, but in the end, human perception will always be the most decisive. Hence, the importance of having a physical model. It's not the same to make a three-dimensional design in which a person sees the accessibility of the cup holder, than to get into the car and check it physically. Once the designers have established the vehicle's seats and the basic dimensions, they distribute the other elements around it. In ergonomics, all of us have an area called the "work area" or "work-space envelope." This area is limited by the circumscribed area in the functional arm of the person, or in other words, to all that where we can reach with the arm without moving the rest of the body. In a basic way, we can consider that the main control elements will have to be in that area, such as lights or turn signals. Then they will add less essential elements. That is why multi-function steering wheels are so good, from which you can control music, air conditioning, navigation, etc. Ergonomics experts consider many more factors, including limitations due to seatbelt use. But it helps us, without being experts, to define in a basic way the interior of the vehicle and its instrumentation. Regarding the field of vision, people have a binocular field of vision of 120 degrees. That is, if we look straight ahead, we will see with relative clarity what is 60º to the left and 60º to the right. Only for objects that are 30º to the right or 30º to the left it's not necessary to move the eyes, once the field of vision is widened, people need to move their eyes, even if they don't move their head. This is important to keep your eyes on the road. From that opening of vision (30º), people tend to turn their heads slightly to better visualize the object. This means that the main objects will be more centered to the pilot's center line, that is, closer to the steering wheel. From 45º to 60º people turn their heads, so it's advisable to leave that area for commands that are used occasionally, or that are used when the vehicle is parked. When tilting the head, the driver is comfortable for objects that are 15º both above and below his line of sight. Although, if necessary, we can easily visualize objects that are 45º above our line of sight or 65º below it without moving our head. This gives us clear figures to design the interior of a vehicle: We locate the position of the driver, we take a logical percentile of a person and we "accommodate" in the seat. We then draw the field of view and identify the areas where it's easiest for you to see objects without turning your head to position the main functions of the vehicle. In reality, more factors go into the design and we would have to consider that the car seat changes position. To solve this, ergonomics specialists use a technique called eyellipse to consider a wider range of options when defining the interior space of the vehicle. After the designers define the interior elements of the vehicle, they work on the exterior visibility of the vehicle trying to eliminate blind spots and elements that obstruct the driver's view such as the car's own dashboard. For example, a bulky or elongated hood limits the driver's view of the asphalt. Glass reflections and glare are also considered, whether due to the windshield or the shiny surfaces or lights used in the passenger compartment. Designers initially work on driver visibility without adding aids, not even rear-view mirrors. The mirrors and other elements will only be added once the elements are fixed inside the vehicle. The latter is called "indirect vision" since it is necessary to have a device to be able to see, even if they are as basic as the rear-view mirrors. At present, this is supported by the use of cameras that help the driver to have greater visibility. In addition, the head-up display that allows the user to see the vehicle information on the windshield, so they don't have the need to take their eyes off the road.

Currently, ergonomics is combined with anthropometric, biomechanical and psychological studies to improve the consumer experience in the vehicle.

Anthropometry is based on the study of the dimensions of people in relation to the environment, so it's directly related to the safety of people. In other words, it helps us to size the cabin and to position the driver. Biomechanics is the study of the mechanical aspects of a biological system, so it treats the human body as if it were a structure. Therefore, biomechanics analyzes the effect that different external forces produce on the human body, for example, the muscular effort required to turn the steering wheel in a parking maneuver.

In the following posts we will continue to see the tests of the vehicle, making special mention of the materials and vehicle dynamics.

0 Comments

Leave a Reply. |

RSS Feed

RSS Feed