Free Automotive Design Course

Automotive Design & Marketing Management

Welcome to the fifth post of the Automotive Marketing and Automotive Design Course. Last week we saw the trends of the automobile, both technological and market, this will redefine how the automotive designer will conceive new vehicles. In addition, the car designer will have to study how the cars interact with the environment and how it will reach the public. In this post we will see automotive design trends, both technological and styling aspects. We will also see a historical introduction to automotive design offered by the Luppo Design school. In the next post we will study the styling phase. We will start by looking at the car design language, which is key in automotive design, especially when we make a design aimed at a specific brand.

TRENDS IN CAR STYLING

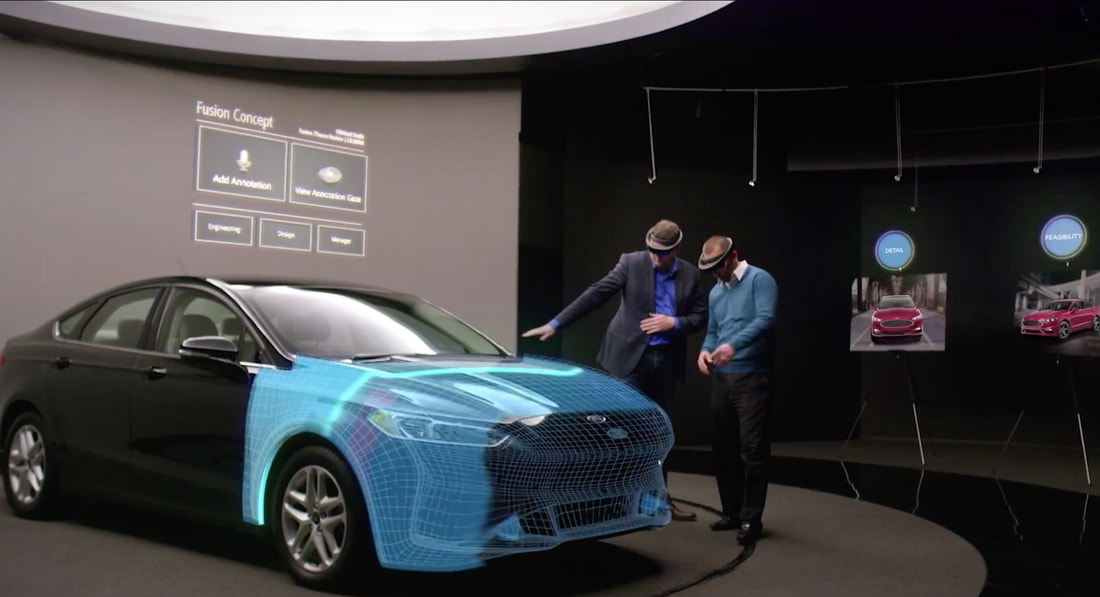

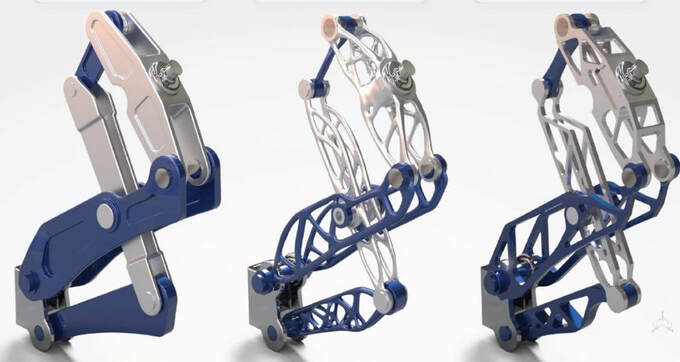

Trends in car styling1 - 3D Printing: Although it's a technology with more than 40 years of history, in recent years it has been widely applied in the industry. It can be used in production, especially in small series vehicles, but its great advantage is the rapid prototyping. In addition, at the production level, 3D printing allows creating different pieces with the same machine; so it's not necessary to create different molds for each type of piece. This allows the designer to offer alternative designs that allow the possibility of customizing the vehicle, without having to add new machinery and new factory production lines. 2 - Augmented Reality: Augmented reality is becoming increasingly important in the design process, this halves the number of clay models. Although creating the digital model is not a quick task, it's four times faster than creating the model in clay and much cheaper. We have to consider that a full-scale clay model represents a total cost of up to € 250,000. In addition, with augmented reality the designer enjoys a much greater immersion, being able to focus on all the details and perform some simulations of the vehicle. This also allows to shorten the car design cycles. As we saw at the beginning, the complete car development takes five years. Currently there is a tendency to try to shorten this time and be able to develop new vehicles in two or three years. Augmented reality is also being used in other areas: On the assembly line, simulating the operators movements, and at sale counters to offer end customers a better shopping experience.

3 - Digital Twins: Big Data and the improvement of artificial intelligence give rise to the so-called “virtual twins”. It's an advanced simulation system that replicates an existing product or industrial process using real data.

These systems allow digital simulations to be done without endangering its physical counterpart, which it's especially useful in production processes. Due to this, we can accurately simulate the effects produced with the introduction of a design change, feeding back from the factory data in real time. You can also create a virtual replica of the vehicle and, using sensors, compare it with the real construction and perform various tests without affecting the physical model. 4 - Vehicle lightweight: In order to comply with emissions and reduce vehicle consumption, a further lightening of the vehicle is currently being sought. This is achieved, for example, with the use of lighter materials such as aluminum and magnesium alloys. Another current solution is to reduce the displacement and size of the engine, known as downsizing. This doesn't imply a technical improvement, but it's a way to adapt quickly to the emission regulations. We can use Cad programs to optimize and simulate parts under certain contour conditions.

PRODUCT CONCEPT

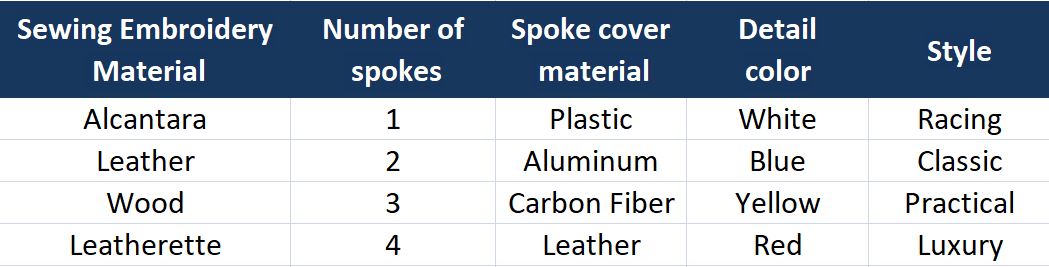

Automotive Product ConceptThe name of this phase varies depending on the manufacturer. The Product Concept is a document created to set all the guidelines and design requirements of the next brand model. An incorrect interpretation of the customer needs, an incorrect market resizing or an incoherent positioning, can lead to a commercial failure of the brand with millionaire losses for the company. At this point, we create a quick car concept, so that the styling department has some sketches and initial requirements as defined as possible. These requirements also goes through a team of ergonomics experts to give their advice on vehicle design. This entire initial phase requires more than a year of work, sometimes even two; although the trend is to reduce these times. We consider a lot of factors and the information provided by market studies. For example: The acquisition cost of these technologies, market size forecasts, sales, fuel cost in the next five years, needs for new manufacturing and assembly facilities, etc. We are facing the first crucial decision, if the project advances, means that the brand will be willing to invest large economic amounts in the project. Still, there're many decisive steps before the new model becomes a reality. So many car concepts don't go beyond the drawing board, or a concept-car displayed at an international motor show. One of the techniques used in this phase is the morphological box, or morphological technique. It's really simple, like doing a puzzle. We have to do tables in which each attribute is set in a column and we combine the possibilities. Then the less logical combinations are eliminated. In this way, we will only have to decide between two or three acceptable combinations. We show you a fairly brief example for a steering wheel: For example, in the development of a popular B-segment compact car. One of the requirements that the marketing team asked for is that the car would have a roadster-style. We must consider that a roadster is a convertible two-seater car, and the B-segment compact car has five seats and a hard top. How is this need transferred? For this, the design team took the following solution: They established the layout of the front seats of a roadster such a Mazda MX-5. Afterwards, a team of ergonomics experts ensured the validation of the concept, meeting safety standards and suitability for the B segment. For example, the seats in a compact car will not be as low as in a roadster; but it came as close as possible. Thanks to this, the compact car offered a driving experience as close as possible to that of a roadster. In addition, the good dynamic capabilities and good engine performance of the vehicle helped to achieve this sense of sportiness.

Another similar technique is Conjoint Analysis, which measures the group effects of a series of attributes and characteristics on consumer perception. We have to take a neutral reference vehicle and then we will draw variations of a series of elements. These elements can be, for example, five different headlights, grills, rear-view mirrors and five different profiles of the vehicle. Then different possible variants are made with a program like Photoshop.

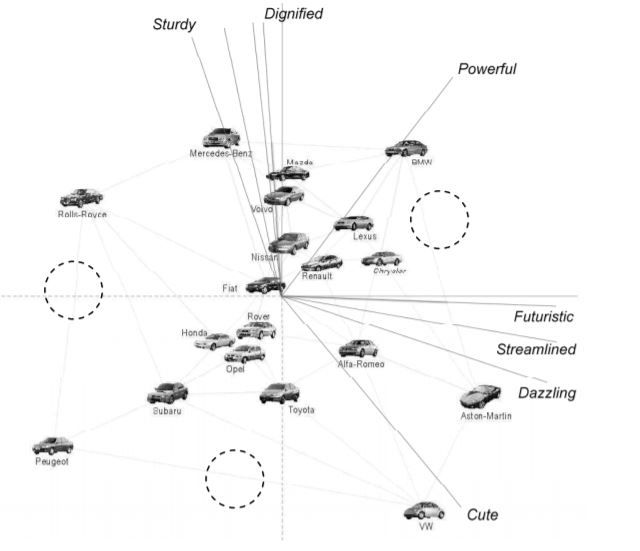

Next, we list different attributes and their antonyms in pairs: comfortable-uncomfortable, cheap-expensive, fast-slow ... As a last step, we take a group of people to show them the different combinations of the vehicle. These people must indicate with which attributes they identify the vehicle the most. This seeks to measure the influence of the elements on people's perception. This is done for each pair of attributes, for example for the duo: "cheap-expensive" we look at the impact against the different combinations, to find which elements are related to the perception of price. Regardless of whether it affects positively or negatively. A perceptual map of car shapes can also be created to show how these shapes evoke affective responses in the user.

In this phase, we will give estimates of development and production times; in addition to the costs, personnel and necessary productive means. We will also define some technical and organizational aspects. Although all this will be optimized and clarified as the car development progresses. It's important to have deadlines by which a series of vehicle tests should have been completed, so that delays can be detected and taken action before it's too late.

All this results in documents that are highly secret and will be sent to the brand's design center. The commercial success or failure of the models that the brand will launch in five years will depend on these documents. At drivingyourdream we have been able to access part of these secret documents, although we cannot publish the information, it has allowed us to develop this posts. Product Concept - Product lineThe brand must be able to introduce a new model to the market at the exact moment that consumers want it, and with the appropriate technologies. This is why, no matter how much we initially define the vehicle, it will always undergo some changes as it develops. For a vehicle program to be profitable for the brand, demand must be sustained throughout its useful life, until it's replaced by a new version. Introducing a new model to replace the old one is also a crucial decision. Normally, to keep the brand image, it's advisable to renew, even slightly, the models every two or three years. If this weren't done, the customer would feel that he's buying a vehicle identical to one that has been on the market for the last three years. So he may choose to purchase a second-hand one, and this wouldn't encourage the manufacture of new cars. In addition, the consumer quickly tires of the novelties and after two or three years it's necessary to introduce new changes. The dilemma arises when a model is selling really well, Why change it? Will the new one sell just as well? Knowing these kinds of questions gives designers an advantage. So understanding the needs, motivations and fears of the brand when introducing a new vehicle to the market can be the success key for the automotive designer. It's very important today that a manufacturer can offer a wide range of products that are positioned at different strategic points in the market. For a designer, it's important to know the concept of economies of scale, that is, the ability to reduce unit cost by increasing production. This shouldn't only apply to a specific model, but to the entire product line of the car brand. If the same machine can manufacture the same part for several vehicles, it can represent significant savings. Assure continuity to the manufacturer's product line is important both for the brand identity of the vehicles and for the cost savings it entails. In this way, the production costs of the different models are similar, except for the motorization. For example, a segment D sedan will cost about 25% more to manufacture than the compact in segment B, within the same line. The designer must adapt to this, and create models with common characteristics and in accordance with the brand's design language. After all, both models go through the same validation tests (dynamic tests, crash tests…), the same regulatory costs (certifications, approvals), and the manufacturing and assembly process is practically similar. A segment-D vehicle with respect to a segment B, with the same engine, becomes more expensive in materials. But in the overall process of car design there is not that much difference in manufacturing costs between the two segments. A manufacturer usually makes more profit from selling models in a larger segment than a smaller one. A current trend is to position B segment models within the Premium sector to increase profit within this category. This happens for example with Abarth for Fiat. Once we have the product concept, in the next week we will see the next stage: Automotive styling. If you missed any of the previous posts, the complete index can be found here. Please, comments and sharing this course on social media, we really appreciate it.

1 Comment

|

RSS Feed

RSS Feed