Kurek GTS / GT7Lightweight design for a lighter world Since 1970, Heinz Kurek, an Original Equipment Manufacturer registered in the German Federal Motor Transport Authority (Deutsches Kraftfahrt Bundesamt, KBA) has been building different sports prototypes that are approved for the public road traffic. The Financial Times Deutschland writes: "Enzo Ferrari was still able to design and assemble the cars himself according to his wishes. Are these days gone? Not at all: Heinz Kurek proves the opposite. It takes a lot of expertise, an energetic will and a pronounced weakness for sports cars. Kurek has built nothing else all his life. Sports prototypes represent one of the greatest challenges in complete vehicle development - they are described as the pinnacle of high end technologies. "Sports cars like Kurek's prototypes," says Christian Wüst, editor of the "Science and Technology" department at the renowned SPIEGEL are the most expressive indicators of the industrial culture (capability), of a company, a country, indeed an entire epoch. Sports prototypes are and will be made for the pure joy of the automobile and hardly anything provokes the opponents of the automobile as much as sports cars of this highly emotional kind. Due to their extremely low weight, Kurek's sports prototypes are characterised by extraordinary driving dynamics, which are characterised by outstanding agility, precise steering behaviour without phase shifts, the necessary torsional stiffness and excellent acceleration values. Robert Tomitzi from SWR explained: "The Kurek GT6 (...) is built in Germany's smallest car factory. The GT6 boasts the driving performance of a race car." As energy and resource efficiency, environmental and climate protection are becoming increasingly important the requirements profile in a goal and result orientated project definition and planning of Kureks sports prototypes is therefore also increasing as sustainability aspects and constantly tightening approval conditions play a central role in the vehicle realisation of the new Kurek GT8. No other type of vehicle offers the engineering comparable opportunities to demonstrate their individual skills. Road-legal sports prototypes like Kureks GTS – GT7 (GT8) represent the highest end of engineering skills in automotive construction and design. These are innovation projects, whereby innovations only come into being when the idea on which they are based is actually approved for public road traffic. Initial premises, iterations, goal validation and core-goal conflicts in project planning and steering influence the sports prototype development process which is already in the "early phase". As (ultra) lightweight exhibits with a homologated registration weight of less than 800 kg (including driver and a bit more than 80 l fuel), Kurek's prototypes describe the challenging path to improved resource and energy efficiency as well as reduction in CO2 emissions. Lightweight construction is the lowest common denominator for significantly optimised sustainability. The clear overall vehicle architecture of the Kurek prototypes, which can be described as multimaterial across all modules, but at the same time it can be recycled "separately" on the materials side, meets the demands of today's recycling requirements. The intelligent modularity of independent body, chassis, engine, transmission, ... structures is described by Harald Kaiser of the stern as a "dream car made by hand".

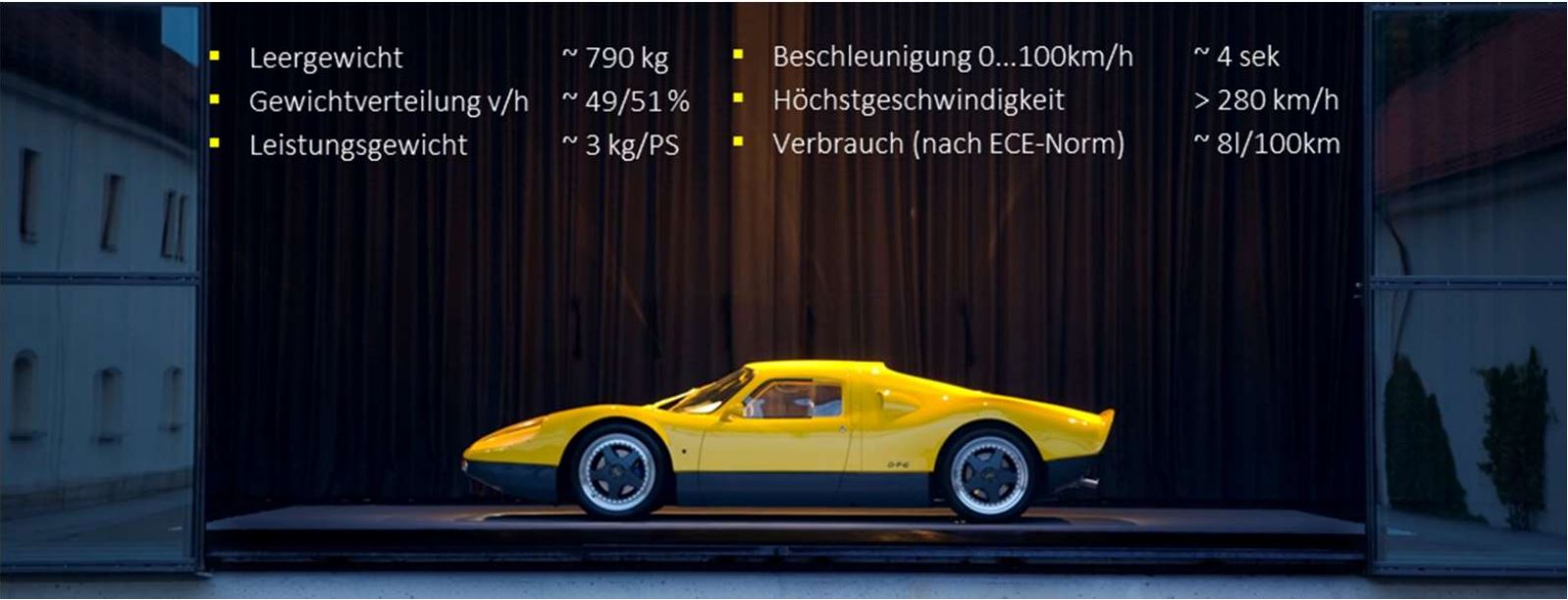

"The aim was to realise outstanding driving performance with a high end efficiency and minimal fuel consumption through extreme lightweight construction and a homogeneous concept", is how car manufacturer Kurek sums up the idea behind the sports prototypes Kurek GTS to GT7 in one clear sentence. The look, feel, impression, gap dimensions, transitions of body modules, exterior and interior components are characterised by particularly high quality, as industrial targets, platform strategies and scaling are of no significance with regard to usual tolerancy requirements. Instead, the sports prototypes enable deliberate individualisation and targeted differentiation, which Michael Koch from "Auto Service Praxis" describes as follows: "There are still idealists who attach importance to the number of units of their car: Kurek is one of them, and because no one could build his jewel in the quantity ONE, he made it himself." Since the energy balance of low energy and low emission vehicles depends on effective, systemic lightweight construction above all, it is essential to implement vehicle concepts that are more effective, more efficient and consequently significantly lighter than the existing ones. The future of automotive engineering will no longer be characterised exclusively by self-supporting bodies (“in Schalen Build”), but by innovative structural and functional "stand-alone" frame concepts that are characterised by an extremely lightweight body structure. From the Kurek GTS to the GT8 (which is currently under development) all sports prototypes have such "independent" frame concepts, which support the extremely light body construction. Analogous to the GT6, which served as a “technology carrier” during the GT8 development and reeled off more than 85,000 km without any problems, the innovative GT8 is also based on the legendary design of the Porsche 904. The philosophy: realisation of a lightweight construction that exactly meets the specific requirements of the manufacturer with a vertical range of manufacture of more than 80%. All Kurek sports prototypes are puristic vehicles. “They have only those performance features that we believe a sports car should have - and none more" The last car would be a sports car - Ferry Porsche once said. It is the clearest statement ever made about the nature of the automobile and the role it plays in society. The sports car embodies the car in its absoluteness. Ferry Porsche's developments were distinguished by the fact that they, like the Porsche 904 - proved their reliability and stability in long-distance world championship races from the legendary Nürburgring to the “24 hrs of Le Mans”. Reliability and stability are also key challenges in lightweight design for public road sports prototypes with a highest end quality. Since about 30% of the total mass of a car is in the body inclusively, the exterior, interior components and the kinetic energy can be determined from ½ mv2 . The vehicle body construction is a central lever for contributing to significant primary energy savings through lighter and thus aiming for consumption and emission optimised vehicles. Lightweight construction does not necessarily have to be cost intensive, but can also be realised at relatively low cost if the conflicting priorities of concept, material, production and functional lightweight construction are precisely analysed and holistically implemented in the whole development.

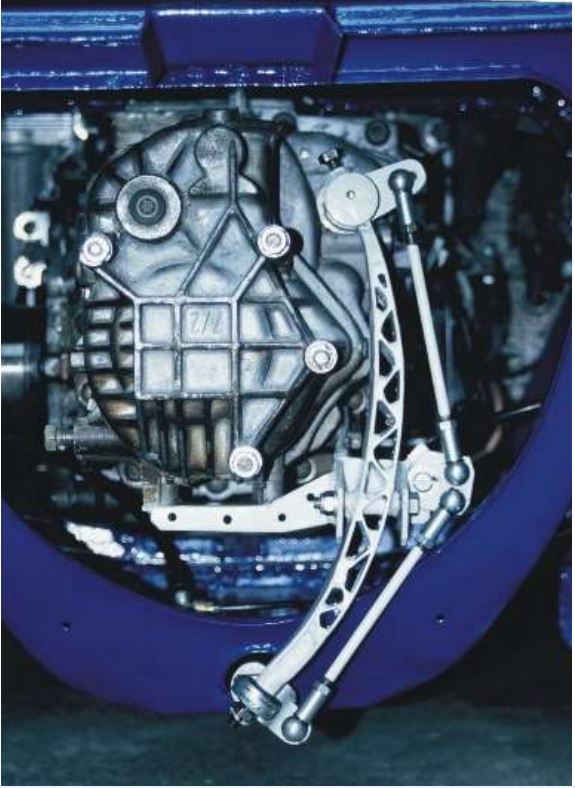

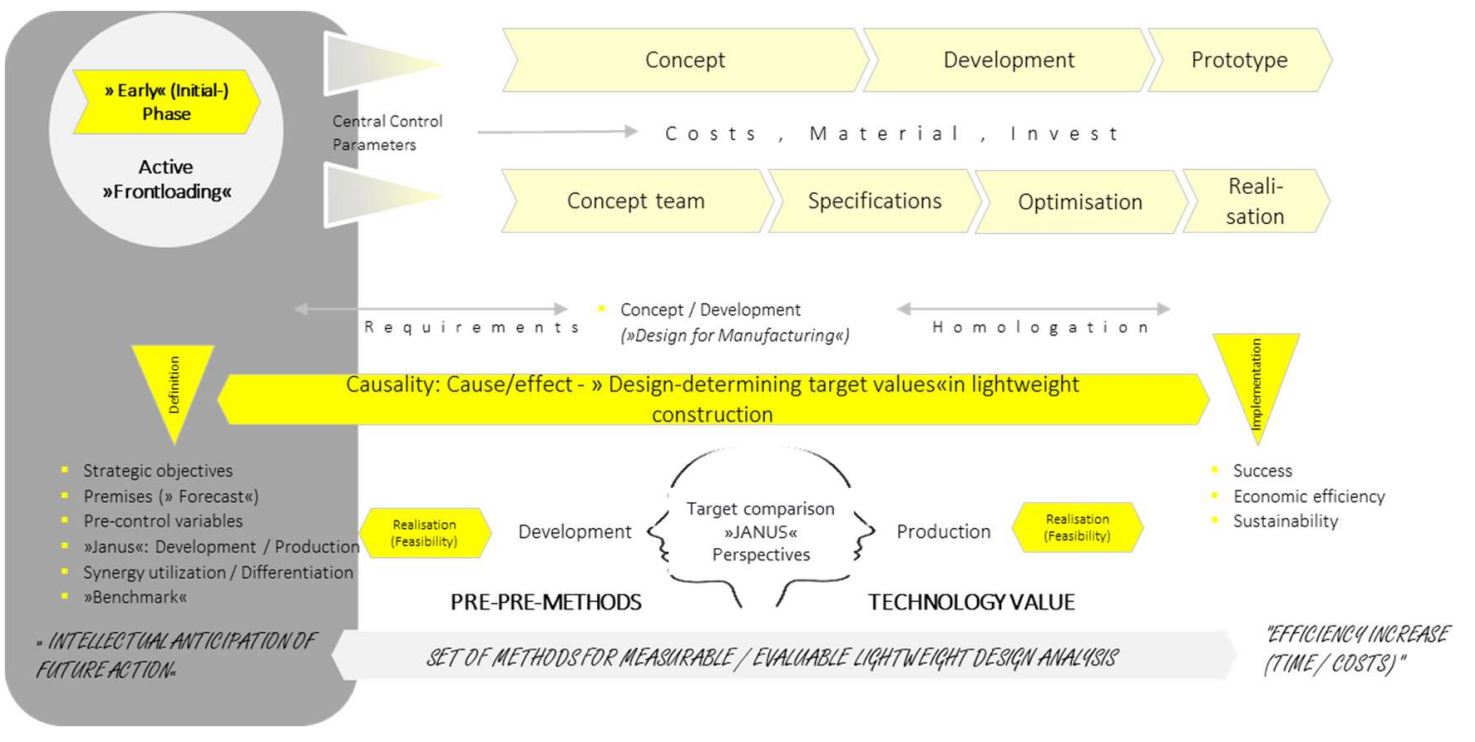

To improve the CO2 footprint, recyclable materials, global warming potential (GWP) , innovative power and strength are necessary, as documented by Kurek's sports prototypes. Innovation projects like these carry enormous risks, and ignorance and misconceptions unnecessarily increase the risk. Studying winning strategies that anticipate early-stage lightweighting challenges in "frontloading" helps to identify the special rules and understand the special knowledge that professional innovation management requires. Figure 8 shows a highly innovative wishbone mount/fixation with a weight saving potential of about 50 % compared to aluminium. With a total mass of 188 grams, tractive forces of 9.3 tonnes are made possible - with 0.25 grams of waste. The process chain from the load spectrum, component planning, topology optimisation and design to prototype construction requires knowledge and expertise in interdisciplinary engineering disciplines. This is only one example of a complete Digital Process Chain. Lightweight construction, sustainability, energy and resource efficiency, environmental and climate protection require a comprehensive knowledge of concepts, materials, functions and production technology that affect the various systems, modules and components and systems of the vehicle. Multiaxial dynamic force and stress analyses require systemic thinking and action, which is what distinguishes Kurek's sports prototypes - from the idea to the final functional component, it is all about innovative power and strength. CAE – CAD – CAM: digital process chains.

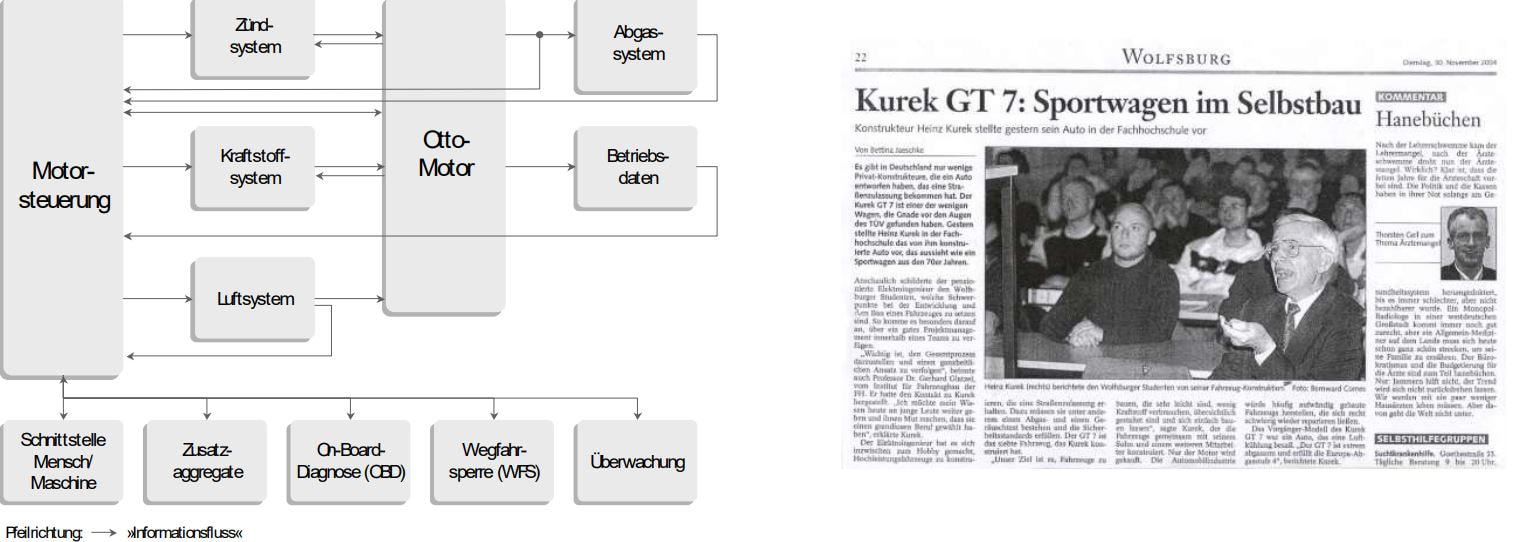

The concept, development and realisation of Kurek's sports prototypes are described by Eberhard Kittler of the "mot" as follows: "This is how you build sports cars - none of it is from largescale production." The central management parameters of Kurek's car manufacturing, whose own vertical range of manufacturing is deliberately more than 80 percent (!), results from the requirements for chassis/body, chassis, drive and interior. Electrical integration functions as a cross variable function, as Figure 9 shows. Against the background of the ongoing electrification in automotive engineering, vehicle manufacturer Heinz Kurek benefits from his expertise and competences in the electrical industries, for which he was responsible for numerous developments that generated a sales volume of about 1.7 billion euros and are based on twelve patents, among other things. This is the differentiation to “Replica”-development companies. This knowledge of experience has always served the transfer of technology, the philosophy of which Thomas Jungmann of "all4engineers" describes as follows: "The philosophy behind Kurek's sports prototypes can easily be described as the revival of the sports prototype class on the road." And Ralf Schepper from "VOX" adds: "The body design is a homage to the 60s and 70s. (...) Kurek builds his cars out of passion, out of love for technology." In the meantime, Kurek has also conveyed this passion and love towards technology to students in more than 120 lectures on automotive lightweight construction and its effects on sustainability. Students from 14 technical colleges and universities have also visited Kurek's factory "live". Working on the new Kurek GT8 has also progressed relatively well despite COVID 19 pandemic. It is to be noted that the Gran Turismo is a sports prototype which has a technical feasibility study of the highest innovative power which will not be for sale. The development measures are based on the experience, knowledge and insights of more than 50 years of sports prototype history. Know-how, profound lightweight design competences and brainware will contribute in improving the Global Warming Potential, recyclable materials and thus improving the CO2 footprint.

Lightweight Design for a lighter World.

0 Comments

Leave a Reply. |

Exotic car brandsFollow us on facebook

|

RSS Feed

RSS Feed